Precisely fine-tuned

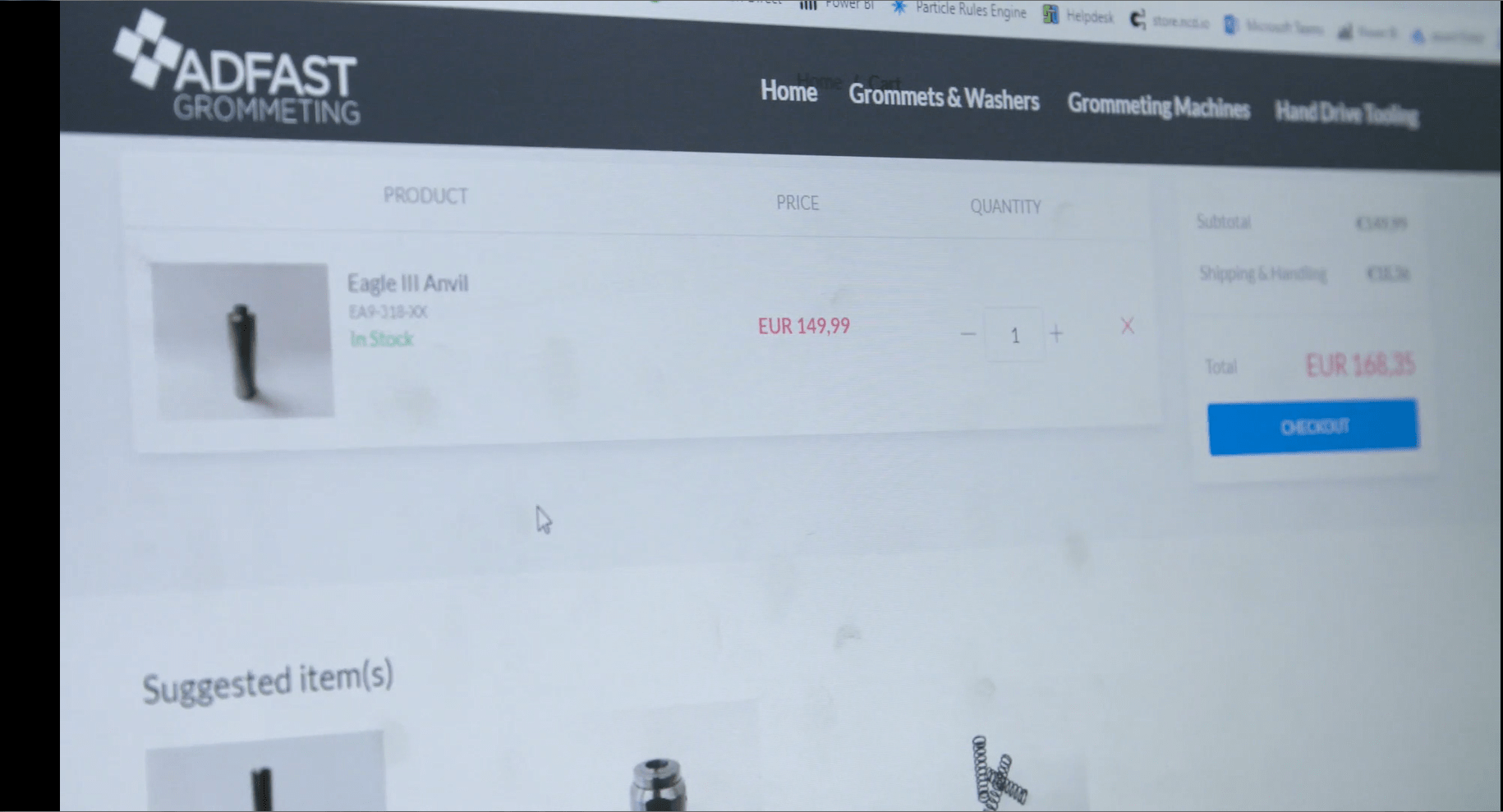

Our interconnected grommeting machine intuitively adjusts to your material thickness, advises you when worn parts need replacement, conducts its own corrective & predictive maintenance, permits reordering of grommets and washers via an online commerce application, and provides production efficiency statistics for you & your team. .

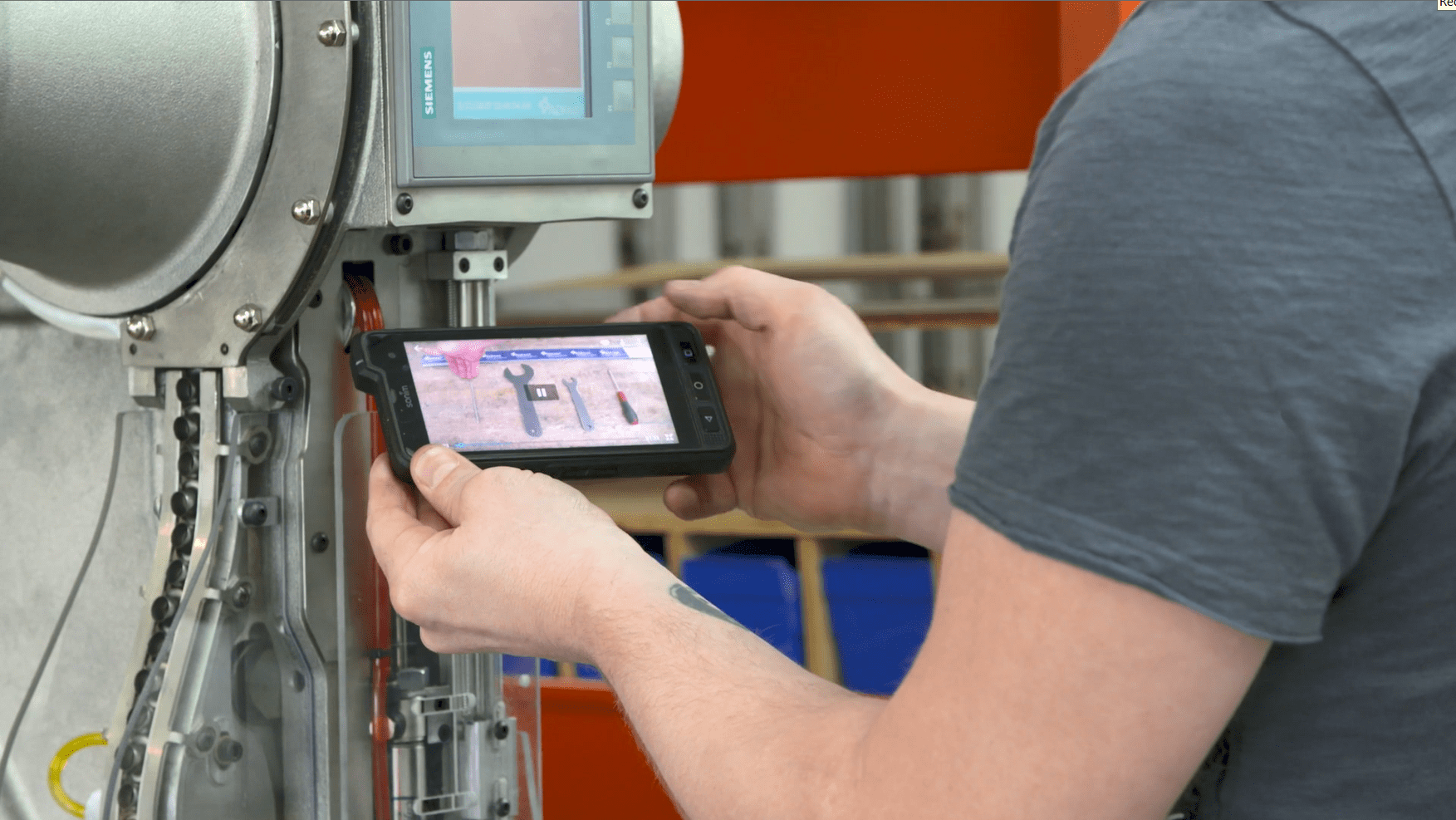

Adfast will present its new Eagle III IoT. The ideal grommeting machine for production lines with limited in-house maintenance capabilities. Rather than hiring a maintenance technician, our Eagle III IoT alerts you when maintenance is required, suggests when parts should be replaced, and shows you how to resolve any issue via a built-in library of instructions and videos.

Regardless of where you are in the World, your Eagle III IoT grommeting machine has your back.

For the last 35 years, Adfast Grommeting has mastered the design & production of grommets, washers, and grommeting machines for all applications and needs. Adfast Grommeting is the only totally integrated business in the industry. It not only designs but also manufactures and distributes its own grommets, washers, and grommeting machines. Family owned since it’s beginnings, it is now currently managed by the third generation.

Adfast Grommeting services a multitude of clients in various countries: from small to large volume, technology savvy to technology shy, near and far. Its manufacturing plant and Headquarters are located in Montréal Canada. Proprietary offices in various cities across North America (Montréal, New York, Toronto, Florida, Missouri, Indiana, Winnipeg, Calgary, Québec) and partners in the Philippines and Australia are equipped to service all your needs.

No matter your material or application, we have the grommeting machine for you. Adfast designs and manufactures all parts as well as assembles each machine in-house, to meet your specific needs. Eagle III machines are intuitive, easy to use, low maintenance, and affordable. From simple to option packed, each Eagle III family cators to different production lines and processes:

Our machines are designed to be modular, thereby permitting you to upgrade at any time. If after purchasing an Eagle III MANUAL you obtain a large production contract and wish to upgrade to an AUTO, just send it back to us.

Precisely fine-tuned

70-90 psi

Easily accesible grommet raceways

Custom material rests

Cast aluminum frames

Well engineered

Brushless grommet and washer bowls

Alerts when setting tools need replacement

Built-in library of instructions and user manuals

Everything at the touch of a fingertip

Escarpment washer feed

Precision setting tools configured to your material

Hand-driven setting tools for small usage

Table-top design

Precise CNC machined parts